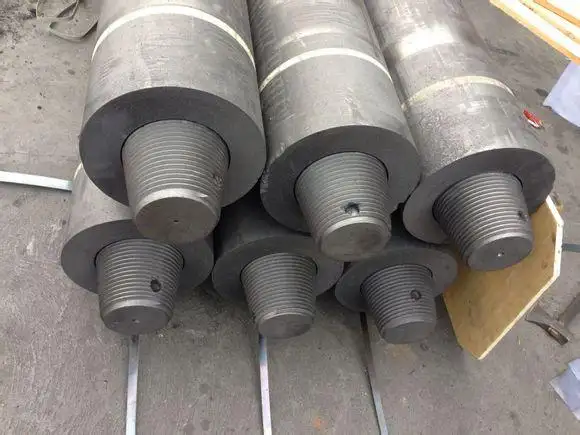

According to the quality index, graphite electrodes can be divided into ordinary power, high power and ultra-high power. It has strong electrical and thermal conductivity, high thermal shock resistance and chemical stability, and easy processing, so it is widely used.

So, as a carbon material, why is graphite electrode so popular?

(1) Strong electrical conductivity and thermal conductivity.

(2) Higher thermal shock resistance and chemical stability.

(3) It has lubricity and anti-wear properties.

(4) It is easier to process, the metal removal rate is high during EDM (electric spark), and the graphite loss is small.

(5) The specific gravity of graphite is 1/5 of that of copper, and the weight of graphite of the same volume is 5 times lighter than that of copper. The large electrode made of copper is too heavy, which is very detrimental to the accuracy of the spindle of the EDM machine tool during long-term EDM. Graphite does not, and it is very safe to handle.

(6) Graphite can have a high processing speed. Generally, the processing speed of graphite is 3-5 times faster than that of ordinary metals. Moreover, choosing the appropriate hardness of the tool and graphite can reduce the wear of the tool and the wear of the electrode.

To purchase graphite electrodes, you are welcome to contact ray group.