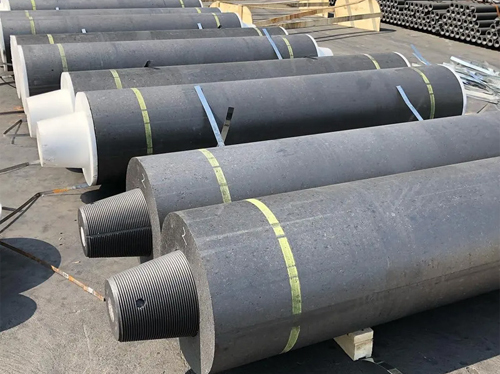

Graphite electrodes are essential components used in modern industries, particularly in the steel and metal industries. These electrodes are made from high-quality graphite material and play a crucial role in various industrial processes. Some of the key uses of graphite electrodes in modern industries are as follows:

Graphite electrodes are commonly used in electric arc furnaces for the production of steel. These electrodes conduct electricity and generate high temperatures that are necessary for melting scrap steel and other raw materials. The graphite electrodes act as a conductor that allows the electrical energy to pass through, creating a powerful arc that melts the materials.

Graphite electrodes are also used in the refining of metals such as copper, aluminum, and zinc. In metal refining processes, graphite electrodes are used to create high-temperature environments that enable the separation of impurities from the molten metal. The electrodes play a critical role in ensuring the efficiency and effectiveness of metal refining processes.

Electric arc furnace (EAF) steelmaking is a common method used in the production of steel. Graphite electrodes are essential for providing the high temperatures needed to melt the raw materials and facilitate the chemical reactions required for steel production. The electrodes are crucial components that enable the EAF steelmaking process to be carried out efficiently.

Graphite electrodes are used in foundries for various applications, including melting and refining metals, as well as shaping and casting metal parts. Foundries utilize graphite electrodes in induction furnaces and other types of furnaces to achieve the high temperatures needed for melting and molding metals. The electrodes play a vital role in enabling foundries to produce high-quality metal products.