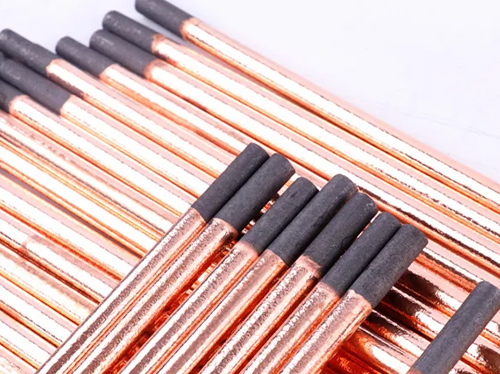

The manufacturing process of copper plated carbon rods mainly includes the following steps:

1. Surface pretreatment of carbon rod

Before copper plating, the surface of the carbon rod needs to be finely treated to remove impurities, oil stains, etc., to ensure a tight bond between the copper layer and the carbon rod. The common method is to first soak the carbon rod in alkaline cleaning agent to remove oil stains, then soak it in acidic solution for acid washing to remove surface oxide film and other oxides, and finally carry out neutralization treatment to avoid adverse effects on subsequent steps

2. Copper plating method

Electroplating: Using the principle of electrolysis, a carbon rod is placed as a cathode in an electrolyte containing copper ions. Copper ions migrate to the surface of the carbon rod under the action of an electric field and reduce and deposit on its surface to form a copper layer. Reasonable selection of electrolyte composition, control of temperature and current density parameters are necessary to obtain a uniform and dense copper layer. For example, in the electroplating copper process of printed circuit boards, by precisely controlling these parameters, the thickness of the copper layer can be made uniform and the conductivity can be good

Chemical plating: Spontaneous deposition of copper atoms on the surface of carbon rods through chemical reactions. This method does not require an external power supply and can achieve uniform copper plating on the surface of carbon rods with complex shapes. But it is necessary to strictly control the composition, temperature, pH value, etc. of the plating solution. Common reducing agents include sodium hypophosphite

3. Preparation of copper plating solution

Copper plating solution is the key to copper plating, usually composed of copper salts, additives, and mixed solutions. Copper salts provide a source of copper ions, and their selection depends on the specific requirements of copper plating and the material of the carbon rod; Additives are used to adjust the performance of copper plating solutions, such as controlling the copper plating rate, improving the uniformity and glossiness of copper layers, etc; The mixed solution maintains the stability and acid-base balance of the copper plating solution

4. Final processing

After copper plating is completed, post-treatment of the copper plated carbon rod is required to improve the quality and performance of the copper layer. Generally, it includes washing with water to remove residual copper plating solution; Drying, evaporating moisture using hot air or other methods; Cleaning and corrosion resistance treatment may also be carried out to further improve the corrosion resistance and service life of the copper layer