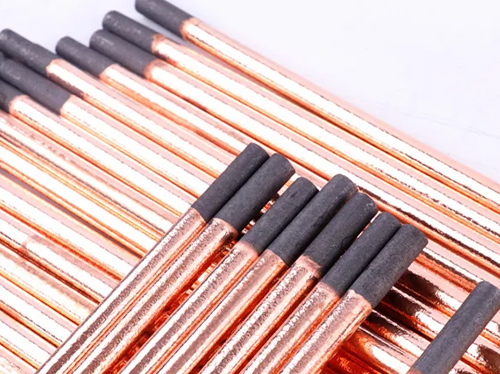

Copper plated carbon rods are commonly used in various industries due to their high conductivity and corrosion resistance properties. Additionally, the copper plating on these carbon rods can help prevent corrosion to some extent.

Copper is known for its excellent corrosion resistance properties. When copper is plated onto carbon rods, it forms a protective layer that acts as a barrier against corrosive elements in the environment. This barrier prevents moisture and other harmful substances from coming into direct contact with the carbon rod, thereby reducing the likelihood of corrosion.

In addition to providing a protective barrier, copper plating can also enhance the conductivity of carbon rods. This is particularly important in applications where high conductivity is required, such as in electrical systems or electrodes. The copper plating helps to improve the overall performance and efficiency of the carbon rods by facilitating the flow of electrical current.

Despite the beneficial properties of copper plating, it is important to note that it is not a foolproof solution to preventing corrosion. While copper is highly resistant to corrosion, it is not completely immune to the effects of certain corrosive substances. Over time, the copper plating on carbon rods may degrade or wear off, leaving the underlying carbon exposed to corrosion.