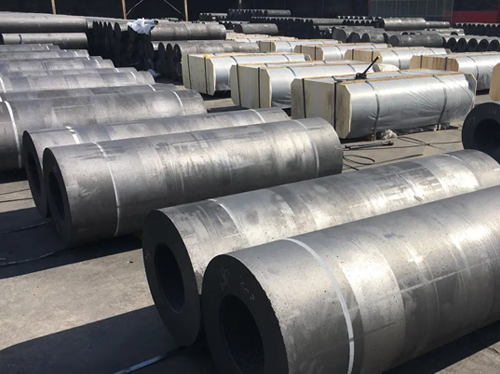

Graphite electrodes are a vital component in the steelmaking industry, where they are used in electric arc furnaces to melt scrap steel and produce new steel. These electrodes are made from high-quality graphite material and are subject to extreme temperatures and conditions during the steelmaking process.

The question of whether graphite electrodes can be reused is a common one in the industry. The short answer is yes, graphite electrodes can be reused under certain conditions. However, there are several factors that need to be taken into consideration when determining whether or not an electrode can be reused.

First and foremost, the condition of the electrode plays a significant role in determining its reusability. If an electrode has been subjected to excessive heat or has been damaged during use, it may not be suitable for reuse. Cracking, spalling, and other forms of damage can compromise the structural integrity of the electrode, making it unsafe to reuse.

Additionally, the quality of the electrode material is crucial in determining its reusability. Higher quality graphite electrodes are more likely to withstand the extreme conditions of steelmaking and can be reused multiple times. Lower quality electrodes may not be able to withstand the rigors of the process and may need to be replaced more frequently.

Furthermore, the electrode’s diameter and length can also impact its reusability. Thicker electrodes are generally more durable and can be reused more times than thinner electrodes. The length of the electrode can also affect its reusability, as longer electrodes have more material that can be worn away during use.

It is important to note that even if an electrode is deemed reusable, it must undergo thorough inspection and testing before being put back into service. Any signs of damage or wear must be addressed before the electrode can be used again to ensure the safety of the steelmaking process.