Application of High Power Graphite Electrodes in Future Metallurgy

Thursday, 09 June 2022

The continuous development of technology, continuous improvement of technology, graphite electrode products More and more irreplaceable importance, many steel mills, silicon plant continues to expand, graphite electrode dosage is also increasing. The graphite electrodes are in the limelight at this time, and at the same time, the quality of graphite electrodes is becoming stricter. High-power graphite electrodes

- Published in blogs

No Comments

What are the advantages of graphite electrode

Thursday, 09 June 2022

Graphite electrode is mainly used in electric arc furnace to heat the furnace charge. Graphite electrode, also known as graphite carbon material, has different quality indexes to adapt to various working environments. Today we talk about the advantages of graphite electrode. The advantages of graphite electrode are easy to process, high metal removal efficiency and small

- Published in blogs

Chinese scientific research team used AI to design graphite

Thursday, 02 June 2022

Recently, it was learned from Hangzhou University of Electronic Science and technology that the research team of Professor Dongyuan from the school of mechanical engineering of Hangzhou University of Electronic Science and technology has combined artificial intelligence, in-depth learning and anti generation technology with the research and development of new materials to develop an artificial

- Published in blogs

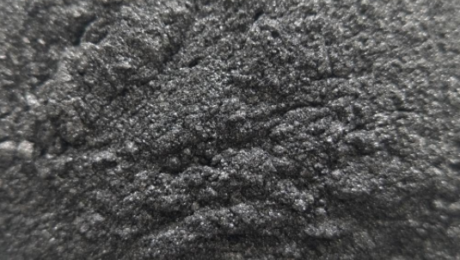

What are the Superior Properties of Graphite Products?

Thursday, 26 May 2022

In recent years, graphite rods, graphite electrodes, graphite molds and other graphite products are used more and more widely, which benefits from the advantages of graphite. Now let’s look at the advantages of graphite products. 1. Graphite products have good adsorption. The carbon pore structure makes the carbon have very good adsorption, so the carbon is

- Published in blogs

Package, Transportation and Storage of Graphite Electrode

Thursday, 26 May 2022

Package of graphite electrode: 1. Separate loading: electrode and joint are packed separately and load respectively. 2. Connection type: one side of electrode connects with joints and then ship by container. The function of package: protect the electrode from damage when storage and transportation, specially protect the screw part from damage. Storage and transportation of graphite

- Published in blogs

Mechanism of graphite high speed machining

Thursday, 19 May 2022

Scholars at home and abroad have carried out preliminary analysis and Research on the crack formation and propagation, chip shape and size, and the interaction between tool and workpiece material in graphite ordinary cutting and high-speed machining. Das believes that when graphite turning is carried out with positive rake tool, a large chip will be

- Published in blogs