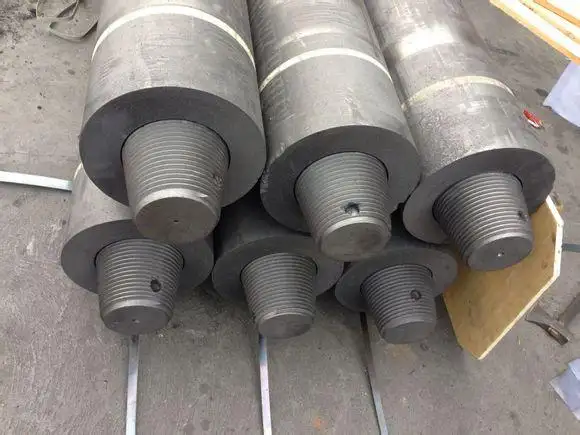

The upstream of the graphite electrode industry chain is mainly petroleum coke, needle coke, coal tar and other raw materials; the midstream is the production and supply link of graphite electrodes, and the main products are ordinary power graphite electrodes, high-power graphite electrodes and ultra-high-power graphite electrodes; downstream applications in steel , yellow phosphorus, industrial silicon and other fields.

From the perspective of global production capacity distribution, China is the world’s largest supplier of graphite electrodes, accounting for more than 60% of the world’s production capacity. Specifically, in the global graphite electrode production capacity in 2021, China will account for 65%, ranking first, followed by the United States and India, accounting for 11% and 7% respectively.

From the perspective of graphite electrode consumption structure, China’s graphite electrode exports account for 43%, and the demand for graphite electrodes in the steel industry accounts for about 41%. Among them, ultra-high-power graphite electrodes are mainly used in electric furnace smelting, and ultra-high-power graphite electrodes are mainly used in out-of-furnace refining. , High-power graphite electrodes; ordinary power graphite electrodes are used in the smelting of metal silicon, yellow phosphorus, and calcium carbide, accounting for 12%, 3%, and 1% of the demand for graphite electrodes.