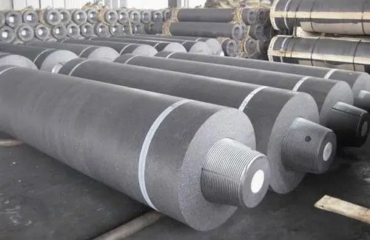

Due to the short supply of carbon products and high profit margin, the economic benefits of carbon enterprises are generally optimistic, Carbon products once had “black gold” “Carbon enterprises have sprung up all over the country and have grown rapidly to nearly 400. However, there are only more than 40 carbon enterprises with supporting processes and large-scale enterprises. However, there are only two of the more than 40 carbon enterprises with leading products of more than 50000 tons. It can be seen from the development status of carbon materials that there are many small and medium-sized enterprises in the whole carbon industry, which are small and difficult to form effective competitiveness. Take the leading product graphite electrode as an example, The production of nearly 400 carbon enterprises in China reached 450000 tons, more than double the demand. In 2002, the graphite electrode production of 33 carbon enterprises counted was 223700 tons, and there were enterprises not counted that produced about 20000-30000 tons of graphite electrodes and about 20000 tons of imported electrodes. The total resources of domestic production and imported graphite electrodes were 270000 tons, while the apparent consumption of graphite electrodes in 2002 was about 180000 tons, which was far greater than the demand. Due to the contradiction between supply and demand, the market competition of carbon enterprises is becoming more and more fierce, and even the situation of competitive price reduction and disorderly competition appears. The market is difficult to control, which makes the overall benefits of the carbon industry suffer great losses.

In order to meet the market demand, China’s carbon enterprises have made great efforts in recent years to adjust the product structure. In 1997, China produced 5500 tons of ultra-high power graphite electrodes, accounting for 2.5% of the total graphite electrodes; In 2002, 23400 tons of ultra-high power graphite electrodes were produced, accounting for 10.4% of the total graphite electrodes, an increase of 7.9 percentage points over 1997. In 1997, China produced 61000 tons of high-power graphite electrodes, accounting for 28% of the total output of graphite electrodes; In 2002, 85100 tons of China graphite electrodes were produced, accounting for 38% of the total output of graphite electrodes, an increase of 10 percentage points over 1997. Although the product structure adjustment of China’s carbon industry is fast, the large-size ultra-high power graphite electrode required by the market still needs to be imported. Perhaps, China’s carbon industry should continue to accelerate the pace of product structure adjustment and strive to produce large-scale ultra-high-power graphite electrodes to meet the needs of domestic large electric furnace production and reduce imports. If enterprises do not adapt to the market, it is difficult for them to survive and develop. China’s carbon enterprises should speed up the pace of adapting to the market, continuously enhance their strength and actively participate in market competition. This is the way for the development of carbon materials in China.