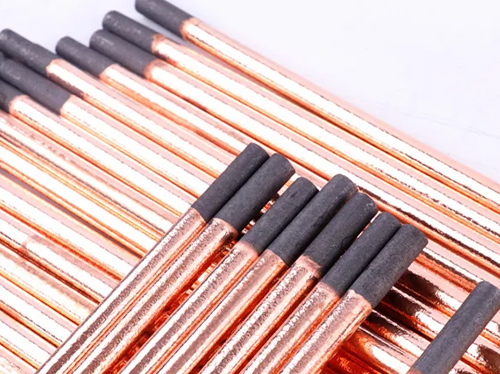

Copper plated carbon rods work by utilizing the properties of both copper and carbon to achieve a desired outcome. Carbon rods are typically used as electrodes in various electrical applications due to their excellent conductivity and durability. However, in some cases, pure carbon rods may not provide the required electrical or mechanical properties for a specific application. This is where copper plating comes into play.

The process of copper plating involves coating the surface of the carbon rod with a thin layer of copper through electroplating. This can be done by immersing the carbon rod in an electrolyte solution containing copper ions and applying an electric current to deposit the copper onto the surface of the rod. The thickness of the copper layer can be controlled by adjusting the duration of the plating process.

Once the carbon rod is copper plated, it gains the benefits of both materials. Copper is an excellent conductor of electricity, much like carbon, but it is also more malleable and corrosion-resistant. This means that the copper plated carbon rod can provide a more stable and reliable electrical connection in applications where pure carbon may degrade over time.

The copper plating can improve the mechanical strength of the carbon rod, making it more resistant to bending or breaking under stress. This can be particularly useful in applications where the rod is subject to frequent handling or manipulation.