Graphite electrodes play a crucial role in the production of steel. They are used in electric arc furnaces (EAFs) for steelmaking, where they function as conductive material to supply electrical energy to melt scrap steel. The process of steel production using graphite electrodes involves several stages, including raw material preparation, electrode manufacturing, EAF operation, and the final steel product. Let us explore in detail how graphite electrodes impact steel production.

Raw Material Preparation: The production of HP graphite electrodes begins with the selection and preparation of raw materials. The key ingredients are petroleum coke and coal tar pitch. Petroleum coke is a hard carbonaceous material derived from oil refining, while coal tar pitch is a by-product of the coal coking process. These materials are mixed and formed into blocks or rods under high pressure. The quality of the raw materials and the manufacturing process affect the properties of the graphite electrodes and, in turn, the efficiency and effectiveness of steel production.

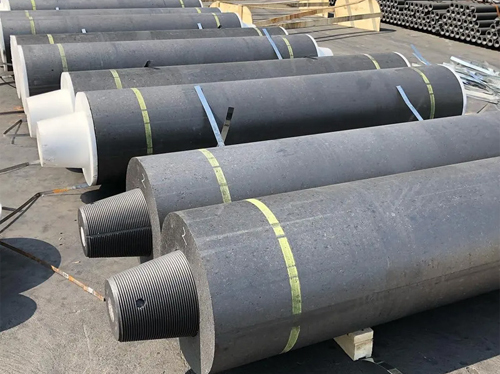

Electrode Manufacturing: The next stage involves the manufacturing of graphite electrodes. The blocks or rods formed from the raw materials are subjected to several treatment processes, including baking, impregnation, and graphitization. Baking involves heating the raw material to high temperatures, which removes impurities and increases the density, electrical conductivity, and mechanical strength of the electrodes. Impregnation involves applying a resin or pitch to fill the pores of the baked electrodes, increasing their mechanical and thermal resistance. Finally, graphitization involves heating the impregnated electrodes to even higher temperatures, which converts the amorphous carbon structure into a more ordered graphite structure. The manufacturing process determines the quality and performance characteristics of the graphite electrodes.

EAF Operation: Once manufactured, the graphite electrodes are installed in the EAF for steel production. The EAF is a high-temperature furnace where scrap steel is melted using an electric arc generated between the electrodes and the steel charge. During steelmaking, the graphite electrodes play a crucial role in supplying electrical energy to melt the scrap steel. The electrodes are placed vertically or at an angle above the steel charge and, when an electric current flows through them, they heat up and create an intense arc. The heat generated by the arc melts the scrap steel and, together with oxygen or other additives, removes impurities to produce high-quality steel. The quality and performance of the graphite electrodes determine the efficiency and effectiveness of the steelmaking process.