Because of the unique properties of carbon-graphite materials, it has a strong vitality when applied in mechanical industry. In particular, running at high temperatures (or ultra-low temperature), mechanical equipment in strong corrosive medium, because of the use of carbon graphite mechanical parts, so that lubrication and corrosion-resistant problems have been satisfactorily resolved, Minchi development speed, only a few decades, carbon and graphite materials have become a mechanical manufacturing industry in one of the general materials. Currently widely used in the manufacture of bearings, piston rings, seals ring, pumps and valve parts, protection kits, bearings, explosion-proof devices and paper machine, such as adsorption tablets.

The use of carbon graphite products in mechanical engineering, from the perspective of the use of the following requirements:

1) The product has the permeability;

2) The products have as much as possible to reduce the grinding performance;

3) Products have good thermal conductivity;

4) The coefficient of thermal expansion of products is small;

5) Products have high corrosion resistance;

6) The mechanical strength of the products, especially the impact resistance;

7) Carbon Graphite materials should have good mechanical processing performance;

8) It is required that the wear and tear should be small, whether used in the condition of thousand or wet type.

9) The price of finished goods is cheaper.

According to the characteristics of the production process, the mechanical carbon graphite material can be divided into the following six categories: Each category has several different grades

1) Calcined hard carbon graphite material;

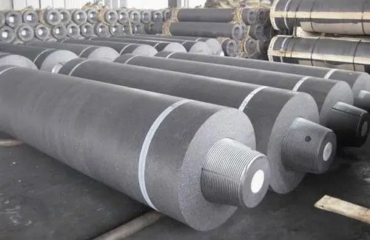

2) Artificial graphite material;

3) The roasting and graphitization materials of the dipping resin;

4) Roasting and graphitization of impregnated metal materials:

5) Graphite material with polymeric resin as binder;

6) Anti-wear Graphite coating material.