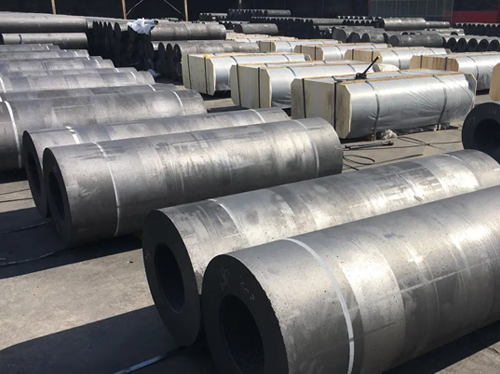

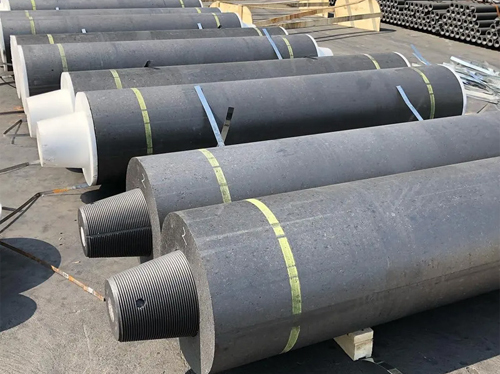

Description

High power graphite electrodes are widely used in industrial sectors where large amounts of electrical current and electricity are necessary, such as electric arc furnaces, ladle furnaces, and electric induction furnaces. In addition, graphite electrodes are also used in other furnace systems, such as electric smelting furnaces and refractory furnaces.

The advantages of high power graphite electrodes over ordinary power graphite electrodes are mainly reflected in the following aspects. Firstly, due to its high thermal conductivity, high mechanical and thermal shock resistance, and high oxidation resistance, high power graphite electrodes are able to work under high temperature, thus improving the manufacturing efficiency significantly. Secondly, an important feature of high power graphite electrodes is their low price. This is because graphite electrodes are made from readily available and inexpensive graphitic materials, which helps to reduce the overall cost of production. Thirdly, their longer service life also makes them a favorable choice for industrial users. Furthermore, the dimensional stability of high power graphite electrodes also means that they are not easily damaged by everyday wear and tear, thereby increasing their operational reliability.

In conclusion, due to their superior resistance to high temperatures, high power graphite electrodes offer a wide range of applications in various industrial sectors and offer a cost-effective and reliable solution to many production requirements.

Our advantage for graphite electrode is: We can produce diameter from 100MM to 800MM (For DIA bigger than 650mm, it is RP GRADE). And different grades according to user’s request.