With the continuous expansion of the application of graphite materials, more requirements are put forward. Therefore, it is necessary to introduce a new complementary process in industrial production to facilitate the acquisition of products with special properties that cannot be obtained by means of general methods. This method is the impregnation and densification of carbon graphite material. The principle of impregnation and densification is to fill the pores of the product about with a substance. However, the effect of impregnation and compaction is still different.

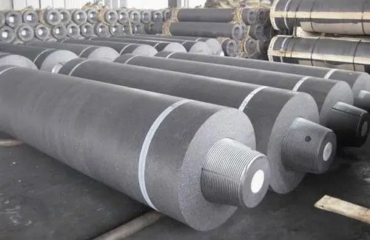

Impregnation in the carbon plant is the baked semi-finished products into the autoclave, at a certain pressure and temperature, so that some liquid-like substances infiltrated into the product blowhole about.

As the coal tar pitch is decomposed into gas in the roasting process, the other part coking is tar about. After roasting, the bulk of the product is much smaller. So that the product in the roasting did not shrink, but in the production: The interior still formed a lot of irregular, aperture size of small pores. such as the true porosity of graphite products up to 25 ~ 32%, the true porosity of carbon products also has 16 ~ 25%. Due to the existence of a large number of pores, the product is bound to produce the chemical properties of cattle. Certain impact. From the foregoing, the true porosity of the product increases, its volume density decreases, the resistivity rises, the mechanical strength decreases, the oxidation speed at a certain temperature is accelerated, the corrosion resistance also becomes worse, the gas or liquid infiltration is easier. Therefore, the impregnation can reduce the true porosity of the product, thus improving the quality of the product.

A substance used to fill the pores, called a impregnating agent. After the impregnation of this material, in the use of inches, not only can not be easily gas, liquid media infiltration, but also to mention ^ it in various media about mechanical strength, corrosion resistance, wear resistance. The selection of impregnating agent should be based on improving the performance of products.

Dense process, is in different forms of carbon, filled with carbon graphite material pore volume. The difference between the density and impregnation is that the material used in impregnation is different from that of the Matrix. The purpose of dense process is mainly to produce high-density products, and sometimes to ensure that products ^ not be gas, liquid infiltration of high-density degree. However, the density is limited, it is not possible to require all the pores of dense products, and can only be dense ^ to the depth of the product-layer. The layer of carbon layer on the surface of another piece of graphite can obviously change the performance of the other piece, and the carbon layer that flash into the orange becomes the other piece. The properties of the compacted carbon layer are described below.