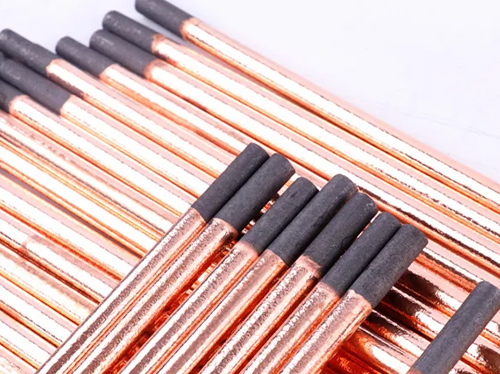

Copper plated carbon rods are a common component used in various electrical applications, from electroplating to circuitry. These rods consist of a carbon core that is typically coated with a thin layer of copper through a process known as electroplating. The combination of carbon and copper offers several advantages that make it an ideal material for certain applications.

The science behind copper plated carbon rods lies in the properties of both carbon and copper. Carbon is a versatile material that is known for its high conductivity, durability, and resistance to heat and corrosion. These properties make carbon an excellent choice for applications where electrical conductivity and durability are important. However, carbon is also a relatively soft material and can wear down over time, especially in applications that involve friction or high temperatures.

Copper, on the other hand, is highly conductive and has excellent corrosion resistance. By coating a carbon rod with a thin layer of copper through electroplating, the rod gains the benefits of both materials. The copper layer provides additional durability and corrosion resistance to the carbon core, extending the lifespan of the rod and improving its performance in various applications.

The process of electroplating involves immersing the carbon rod in a solution containing copper ions and passing an electric current through the solution. This causes the copper ions to be deposited onto the surface of the carbon rod, forming a thin layer of copper. The thickness of the copper layer can be controlled by adjusting the parameters of the electroplating process, such as the current density and plating time.